Services

Stockton Infrared Services

With a history of innovation and a background in real-world applications, our goal is to help both clients and contract service providers by providing quality services and information on infrared thermography. Our primary infrared services include Aerial, Electro-mechanical, Building, and R&D services. Continue to the information below for more information on each.

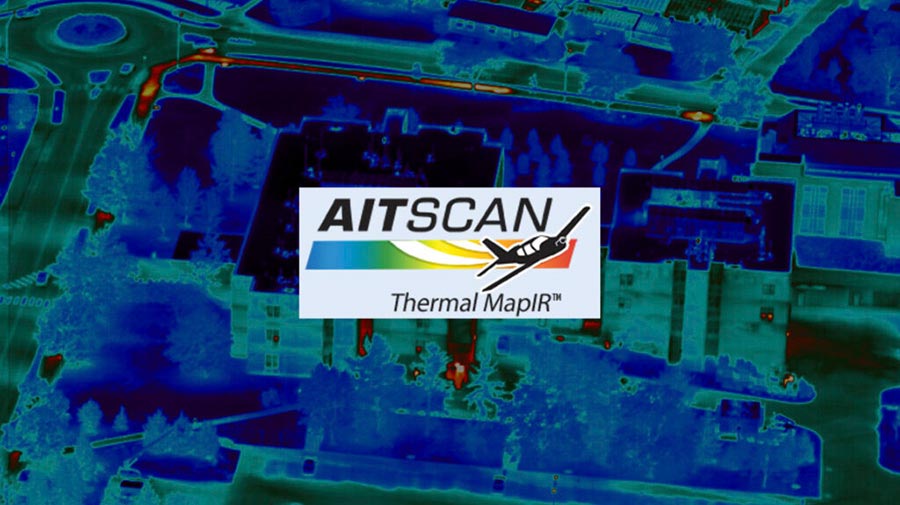

AITScan™

Aerial Infrared

Aerial infrared (IR) thermal mapping can be used by cities, military bases, universities and large facilities to find leaks in district heating and cooling systems, supply water systems, storm water drains and sewer lines. Also, the condition of all commercial building roofs with respect to air leakage, heat loss and moisture in trusion in roofs can be quickly at the same time.

Some of the other uses of high-resolution, thermal IR missions are finding discovering pollution sources in creeks, rivers, lakes and streams, counting animals like deer for municipalities, inspecting high voltage transmission lines for power companies, defining the extent of landfill fires and performing many other specialized aerial IR services.

ElectriScan™

Electrical Infrared

Before an electrical or mechanical component burns up, it heats up. Infrared (IR) thermography is used to perform P/PM inspections on electrical and mechanical equipment because excess temperature indicates excess resistance on electrical equipment and excess friction on mechanical equipment.

Electrical faults such as loose connections, overloaded or imbalanced circuits, faulty breakers, damaged switches, faulty fuses and a wide range of other unwanted electrical conditions can be found by performing IR thermography.

Infrared Thermography is used to see the excess heat (resistance or load) so that problems can be found, and maintenance personnel can act to correct the problem before the component fails -causing damage to the component, safety hazards and/or production downtime.

BuildScanIR™

Building Infrared

Before an electrical or mechanical component burns up, it heats up. Infrared (IR) thermography is used to perform P/PM inspections on electrical and mechanical equipment because excess temperature indicates excess resistance on electrical equipment and excess friction on mechanical equipment.

Electrical faults such as loose connections, overloaded or imbalanced circuits, faulty breakers, damaged switches, faulty fuses and a wide range of other unwanted electrical conditions can be found by performing IR thermography.

Infrared Thermography is used to see the excess heat (resistance or load) so that problems can be found, and maintenance personnel can act to correct the problem before the component fails -causing damage to the component, safety hazards and/or production downtime.

IRresearcher™

Infrared R&D

Research using infrared thermography is gaining popularity. IR technology can be used to test and enhance a myriad of manufacturing processes.

Applications-specific infrared research examples include:

- Carbon fiber composite structures

- Automotive and aircraft inspections

- Micro-circuitry inspections

- Furnaces, kilns and heat treat processes

- Boilers and smokestacks

- Medical equipment manufacturing

- Freezers and cold storage

- Sports medicine

- Too many to list!